Request

Spotting scopes are powerful optical tools. They provide detailed, magnified views of distant subjects. These instruments combine sophisticated lens systems, precise prism assemblies, and tough construction. They deliver outstanding clarity across different distances and challenging environments. Uses include wildlife watching, surveillance, and outdoor sports. Spotting scopes depend on modern engineering. Key features are multi-coated optics, ED glass, and nitrogen-purged housings. These ensure sharp, bright images. This breakdown examines their core parts, optical rules, and durability traits. It offers experts understanding of how these tools perform well in demanding field use.

Spotting scopes are precise optical tools. They give high-resolution, magnified views of far-off subjects. Grasping how they function starts with their core optical parts. These parts control image quality, magnification range, and light transmission.

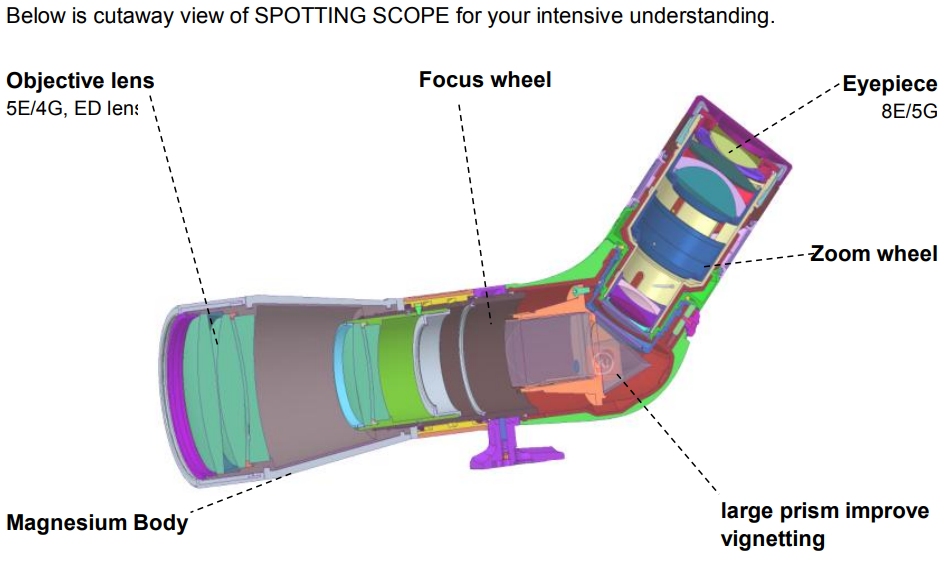

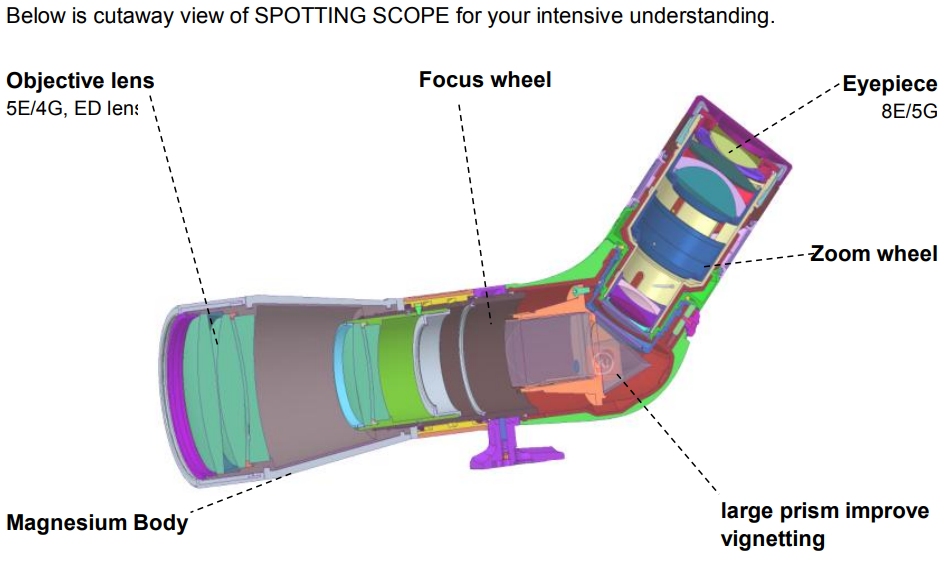

The objective lens gathers light first. Larger objective lenses capture more light. This improves image brightness and clarity. It's especially vital in low light, like dawn or dusk. Top spotting scopes use multi-coated or fully multi-coated lenses. These reduce glare and boost contrast. The coatings cut reflections on glass surfaces. This allows better light passage.

Advanced lens coatings also help with true colors and sharpness. Anti-reflective coatings are layered on all air-to-glass surfaces. This ensures top performance under various light conditions.

Eyepieces set both the magnification power and field of view. Spotting scopes usually have interchangeable eyepieces. Some offer zoom eyepieces. These let users change magnification levels on the fly. For example, from 20x up to 60x. High-quality eyepiece designs use multiple lens elements. This keeps clarity throughout the zoom range.

Eyepiece comfort matters for long sessions. Good eye relief is crucial for eyeglass wearers. It also reduces eye strain during extended viewing.

Prisms fix the upside-down image made by refracting lenses. Two main prism types exist: Porro prisms and roof prisms. Porro prisms give excellent depth sense and wider views. But they make designs bulkier. Roof prisms allow more compact builds. Yet, they need exact alignment and special phase-correction coatings. This keeps the image sharp.

This product also functions as a monocular anti-shaking high-magnification binoculars. It provides stable viewing and is easy to carry.

Hemusun Optical Instrument Co., Ltd. tackles these issues. They integrate modern prism engineering and high-transmission coatings. This guarantees top visual quality while keeping the scope portable.

Keeping images sharp at various ranges is critical. This matters for birdwatching or surveillance. Special optical techniques correct errors. They optimize focus across the whole viewing area.

Chromatic aberration happens when light colors don't meet at one point. This causes color fringes around high-contrast edges. Spotting scopes fix this using Extra-low Dispersion (ED) glass. Some use fluorite elements. These align color wavelengths more accurately.

These materials greatly lessen color distortion. They improve edge definition and contrast, even at high power.

Premium spotting scopes sometimes add field flattener lenses. These remove curvature of field. This distortion makes image edges look soft while the center stays sharp. Corrective elements ensure sharpness from edge to edge. This is vital for scanning wide areas or tracking fast subjects.

High light passage is fundamental for bright, detailed images. Multi-coating technologies improve this. They cut internal reflections within the light path. Fully multi-coated systems boost contrast. This helps in backlit scenes or shaded spots.

Thanks to the jitter elimination technology, this device suits many situations. Examples are handheld use, travel by car, boat, and flying.

Hemusun Optical Instrument Co., Ltd. uses special glass for color correction. They combine it with unique coating methods. This delivers steady clarity under diverse environmental conditions.

Focusing systems are vital. They help get precise images at different distances quickly. Accuracy matters under dynamic field conditions. Targets might shift rapidly.

Internal focusing moves lens groups inside. It doesn't change the scope's outside length or balance. This suits harsh places. External movement might let in dust or cause wear. External focusing adjusts by extending barrels. But this can harm weather sealing if poorly designed.

Internal focusing also lowers misalignment risk over time. It does this by reducing stress on moving parts.

Dual-speed focus knobs give coarse adjustments first. These allow fast targeting. Then, fine-tuning controls let users get exact focus. This is needed at high magnifications. It stops overshooting the focus point. Such a system is essential for wildlife watching or tactical surveillance.

Precise machining ensures focusing parts work smoothly. There should be no looseness or play. Any slack can harm accuracy. This is true especially for small targets far away. Tolerance control affects not just use but also long-term toughness under repeated handling.

Hemusun Optical Instrument Co., Ltd. builds dual-speed precision focusing into its products. They use tight mechanical tolerances. This backs professional-grade target finding under demanding conditions.

Toughness defines professional spotting scopes. They are used outdoors year-round in extremes. Places range from dry deserts to icy tundras. Engineering must match this demand.

Waterproof housings stop moisture getting in. They use O-ring seals around all joints and openings. Fog-proofing involves nitrogen or argon gas inside sealed barrels. This replaces moist air. Moisture could condense inside during temperature changes. The process keeps views clear despite humidity levels.

Magnesium alloys or polycarbonate composites are preferred. They offer strength without too much weight. Corrosion resistance is key for long life. Portability during long treks is also important.

Advanced sealing uses rubber gaskets. They go around eyepieces, objective lenses, focus knobs, and tripod mounts. This isolates the optics completely. It stops dust particles or airborne dirt. These could harm the optics over time.

Hemusun Optical Instrument Co., Ltd. uses military-grade waterproofing. They apply inert gas purging across their housings. This ensures readiness under big temperature swings or rain.

Spotting scopes come in two main styles: angular (angled) or straight-body. Each offers comfort benefits. The best choice depends on the situation and user preference.

Angled scopes allow comfortable viewing from low positions. Think sitting or lying down. Users avoid awkward neck angles. Sharing among people of different heights is easier. Tripod height doesn't need constant adjustment. Straight scopes align naturally with line-of-sight targets. They are preferred for tracking fast subjects. Examples are aircraft or game animals on level ground.

Angular designs work best for birdwatching from hides or high points. Straight models suit quick acquisition tasks. Hunting or marine navigation are examples. Here, fast alignment matters more than comfort over long periods.

Both types need stable mounts. But angular models often have rotating tripod collars. This allows flexible orientation changes. Users don't need to reposition the whole tripod. It's a key feature for panoramic surveys or team sharing.

Hemusun Optical Instrument Co., Ltd. makes both angular and straight-body scopes. They engineer them for comfort and adaptability. Mounting suits universal standards. Designs fit mission needs from hobby use to industrial surveillance.

As a leader in optical innovation, Hemusun Optical Instrument Co., Ltd. provides full solutions. They focus on reliable performance in real-world use. Customers range from birdwatchers to industrial monitors.

Hemusun has strong R&D skills in precision optics. They use decades of experience. They produce high-performance monoculars. This includes anti-shake telescopic systems. These give stable viewing and are easy to carry. Such innovations extend to their spotting scopes. Unique stabilization tech is key. It even works with smartphone telephoto add-ons. This captures distant details well on mobile platforms.

Options go from entry-level compact units. These focus on portability. Up to pro-grade models. These feature ED-glass objectives and dual-speed focus dials. Hemusun’s catalog covers many needs. These include tourism, race watching, bird watching, and search and rescue. Such tasks demand stable long-range performance on varied terrain.

Each unit faces strict quality checks. Protocols match international ISO standards. Testing simulates environmental stresses. This ensures resistance against shocks and vibrations. These occur during transport by car, boat, and flying. Hemusun’s global supply chains support this worldwide.

Designing an effective spotting scope means balancing priorities. Examples are optical performance versus weight. Thermal stability must also hold under changing outdoor temperatures.

High magnification makes small errors bigger. Thus, optics need precise alignment. Phase-coated prisms help reduce distortions. Clarity stays good throughout the zoom range.

Temperature shifts make housings expand or contract. This can affect alignment. Modern scopes use floating lens mounts. Thermally stable materials like magnesium alloy frames lessen these effects.

Getting portability without losing sharpness needs clever design. Folding prism paths (like roof prisms) help. Lightweight yet strong chassis are vital. Hemusun’s design approach integrates this. They blend mobile ease with top visual results.

Careful engineering makes spotting scopes work well. It includes advanced lens formulas, strong mechanical design, and user-friendly ergonomics. Strict quality control backs this up. The result is high-performance imaging. Professionals need this across fields. Uses cover environmental research and tactical operations.

Spotting scopes are best for land viewing. They use lower magnifications but give wider views. Telescopes are mainly for star watching. They need higher power but show narrower fields.

Yes—models with large objective lenses (often 60–80mm) work well. Fully multi-coated optics help gather enough light. This works even at dawn or dusk.

Store your scope safely using padded cases. Avoid hard knocks. Choose scopes with internal focusing. This lowers risks from external movement. It helps keep alignment correct long-term.